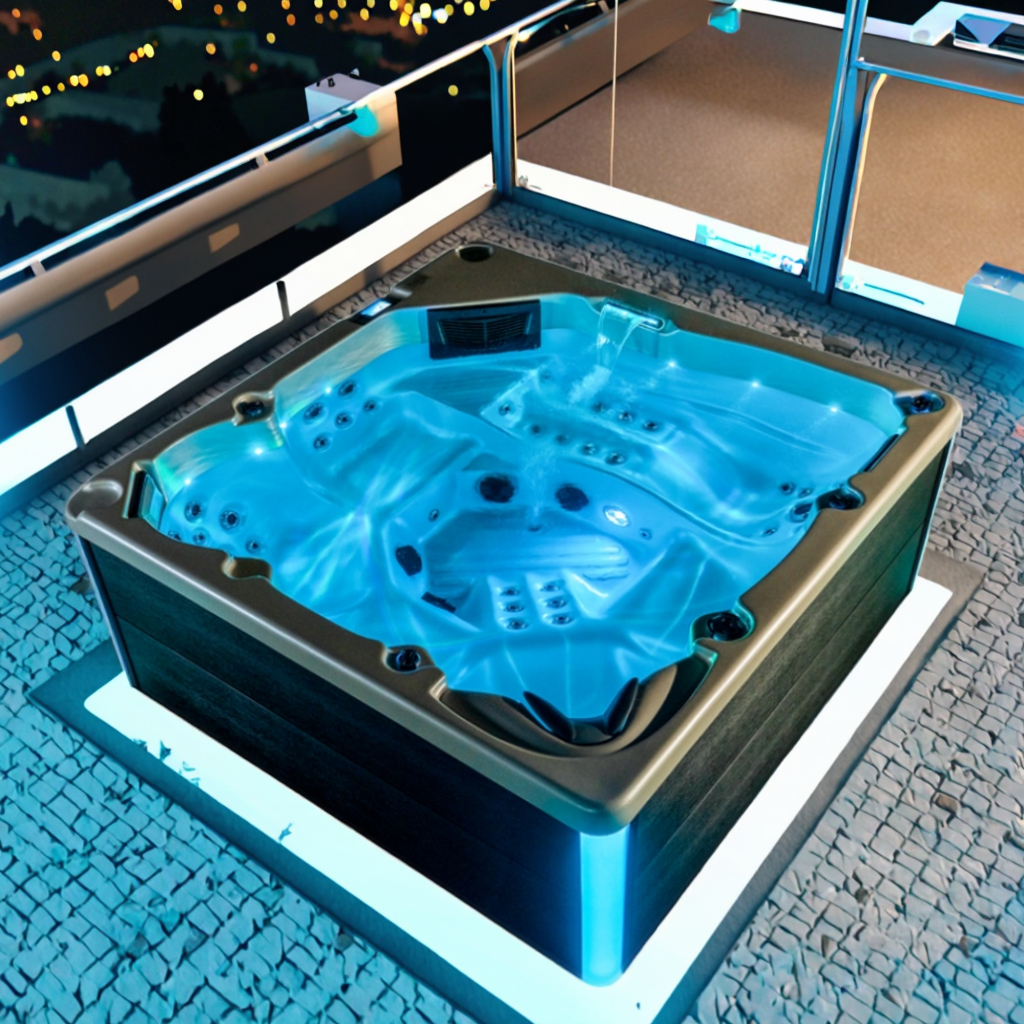

Whirlpool spa hot tubs are increasingly favored by families and high-end hotels for their soothing, blood circulation-promoting, and muscle-relaxing effects. However, many users encounter jet clogging during daily use. If not addressed promptly, this can not only affect the user experience but also potentially damage the internal system of the whirlpool spa hot tub.

So, how should we deal with a clogged whirlpool spa hot tub jet? What are the consequences of clogging? This article will provide a comprehensive analysis.

Why do whirlpool spa hot tub jets clog?

Clogged whirlpool spa hot tub jets are not accidental and are usually related to the following factors:

1. Water quality issues

Long-term accumulation of minerals, calcium and magnesium ions, and sediment in the water can adhere to the inside of the jet, forming scale, reducing water flow or even causing complete clogging.

2. Infrequent Cleaning and Maintenance

Whirlpool spa hot tub nozzles and pipes require regular cleaning and disinfection. Neglecting maintenance can lead to build-up of dirt, dander, and grease, causing nozzle blockage.

3. Chemical Deposits

Whirlpool spa hot tubs often use bleach, disinfectant tablets, or softeners. Improper use can cause chemical residues to accumulate inside the nozzles, gradually blocking water flow.

4. Aging or Design Issues in Pipes

With increased use, the pipes of the whirlpool spa hot tub may age or corrode, causing poor water flow from the nozzles.

Understanding the causes of nozzle blockage helps us take targeted preventative measures in daily use, reducing the probability of blockage.

What are the effects of nozzle blockage on a whirlpool spa hot tub?

Normally blocked nozzles not only affect the user experience but can also cause the following problems:

1. Reduced Water Flow and Decreased Massage Effect

Whirlpool spa hot tubs rely on the nozzles to provide a strong water flow and bubble massage. Blockage reduces the water flow, significantly diminishing the massage effect and preventing the achievement of soothing and relaxing effects. 2. Increased Heating System Load: Blockage leads to poor water flow and uneven hot water circulation. This forces the pump and heater to work at higher loads, increasing the risk of malfunction and shortening the lifespan of the Whirlpool spa hot tub.

3. Increased Risk of Bacterial Growth

Blockage causes water stagnation, keeping the water temperature within a range conducive to bacterial growth. Without timely cleaning and disinfection, bacteria and algae can easily proliferate, affecting health.

4. Increased Noise

Blockage can cause abnormal pump operation, resulting in noise, vibration, and even unbalanced air bubbles, impacting the user experience.

As you can see, massage jet blockage is a problem that cannot be ignored. Improper handling can not only affect comfort but also potentially cause equipment damage and health hazards.

How to Determine if a Whirlpool spa hot tub jet is Blocked?

To determine if a jet is blocked, consider the following:

• Significantly Reduced Water Flow: Under normal use, the jet provides a stable and moderate water flow. After blockage, the water flow is significantly reduced or the spray becomes uneven.

• Abnormal Noise: Blockage causes the pump to run dry or increase its load, resulting in a humming sound or vibration.

• Localized dry jet: Some massage jets have no water flow at all, while others continue to function normally.

• Uneven water temperature: Clogged jets can affect hot water circulation, causing some areas to be too cold or too hot.

If any of the above occurs, check and clean the massage jets immediately to prevent the problem from worsening.

What to do if your Whirlpool spa hot tub jet is clogged?

To address a clogged Whirlpool spa hot tub jet, users can take the following steps:

1. Turn off the power and drain the water

Before cleaning the massage jet, always turn off the power to the Whirlpool spa hot tub for safety. If possible, drain the water to easily inspect the inside of the jet.

2. Disassemble and clean the jet

Depending on the Whirlpool spa hot tub model, the jet is usually easy to disassemble. After disassembly, use a soft brush or toothbrush to clean the deposits inside the jet holes and rinse thoroughly with warm water. For stubborn limescale, soak the jet in white vinegar or a dedicated limescale cleaner for 15-30 minutes, then rinse.

3. Pipe Cleaning

If the massage jet remains clogged after disassembly, the problem may be inside the pipes. Use a pipe cleaner or a special flexible brush to gently clean along the pipes and remove internal deposits. Avoid using hard tools to prevent damage to the pipes.

4. Test Water Flow

After cleaning the massage jet and pipes, reinstall the jet, fill it with clean water, and turn on the power to test if the water flow is normal. If the water flow is smooth, the blockage is resolved.

5. Regular Maintenance to Prevent Blockage

• Perform a simple flush and inspection of the jet weekly or monthly.

• Replace the filter in the whirlpool spa hot tub regularly.

• Control water quality; avoid using high-mineral water, or install a water softener.

• Use a suitable disinfectant to avoid chemical residue.

Regular maintenance effectively extends the lifespan of the whirlpool spa hot tub jet and pipes, maintaining optimal massage performance.

Why can improper jet cleaning cause blockages?

Improper cleaning methods can also cause clogging, such as:

• Damaging the nozzle orifice with excessive force: Over-scrubbing or using sharp tools can damage the internal parts of the nozzle, actually affecting water flow.

• Improper use of chemical cleaners: Highly concentrated cleaners can corrode the nozzle material, causing secondary clogging.

• Ignoring pipe residue: Cleaning only the nozzle while neglecting deposits inside the pipes can easily lead to recurring clogging.

Therefore, cleaning Whirlpool spa hot tub nozzles requires a scientific approach and standardized procedures to ensure long-term smooth operation.

What does frequent clogging of Whirlpool spa hot tub nozzles indicate?

If Whirlpool spa hot tub nozzles frequently clog, it may indicate the following problems:

• High water hardness: High-mineral water easily produces scale, clogging nozzles and pipes.

• Infrequent cleaning and maintenance: Neglecting nozzle and pipe cleaning for a long time will accelerate clogging.

• Aging equipment or design flaws: Old equipment or poorly designed piping can also lead to frequent clogging.

To address frequent clogging, focus on three aspects: water quality control, cleaning habits, and equipment maintenance. Identify the root cause and avoid repeated cleaning.

How to reduce jet clogging through water quality improvement?

Whirlpool spa hot tub jet clogging is closely related to water quality. Improving water quality can effectively delay clogging:

• Use softened water or a water purifier: Reduce the concentration of calcium and magnesium ions in the water, reducing scale formation.

• Control disinfectant usage: Use bleach, chlorine tablets, or bromine tablets appropriately to avoid chemical residue clogging pipes.

• Change water regularly: Long-term use of the same water source can easily lead to sediment accumulation. Regular water changes keep massage jets clear.

Good water quality not only helps keep jets clear but also improves the overall hygiene and lifespan of the whirlpool spa hot tub.

How to determine if professional repair is needed?

When cleaning the massage jet and pipes fails to resolve the clogging problem, professional repair may be necessary. The following situations require special attention:

• Poor water flow even after nozzle removal

• Obvious corrosion or damage inside the pipes

• Abnormal noise from the water pump or heater

• Extremely frequent clogging, recurring within a short period

Professional repair personnel can perform deep cleaning or replace damaged parts using specialized tools to ensure the whirlpool spa hot tub functions properly.

What Products Does LOVIA SPA Offer for Sale?

LOVIA SPA offers an extensive product line including spa massage bathtubs, outdoor hot tubs, and modern swim spas. Each product is carefully designed with energy-saving Balboa control systems, LX pumps, and Aristech acrylic shells. As a large-scale factory and supplier, we provide low-price wholesale deals and flexible customization to meet different market demands. Buyers can request quotes for customized models, compare prices, or take advantage of our promotional sales.